Here you find information about:

- What process water actually is

- What legal requirements are applicable

- How you can save money with environmental protection

- How simple centrifugal cleaning of your process water is

- How you choose the best centrifuge for your application

- When flocculation represents the better solution

What process water actually is

Primary goal of the mass finishing process is the deburring, edge radiusing, surface grinding, polishing, etc., of all kinds of work pieces. This involves the removal of a small amount of material from the work piece surface. The process as such is an intensive interaction between the grinding/polishing media and a mixture of water and the finishing compound. This mixture, the so-called process water, discharges all kinds of contaminants, such as metal fines from the work pieces, media fines, oil and grease carried into the process and, occasionally, chelated metals from the mass finishing machine. Of course, then arises the question: “What should I do with the contaminated process water? Should I just discharge it to drain, or can I re-use it in a sensible manner?”

What the water authorities have to say

Untreated waste water – this includes the process water from mass finishing operations – cannot be simply discharged to drain in most countries. Doing so would be a serious violation of the prevailing environmental laws. The users have two alternatives: Running their mass finishing processes with fresh water in flow-through/loss mode and cleaning the generated waste water before discharging it to drain or re-using it in a closed-loop recycling system.

The general water directive of the European Union (directive 2000/60/EG of the European parliament and the EU commission) and the various national laws derived from this directive stipulate that the waste water must be cleaned before discharge. Moreover, it requires an official approval by the water authorities. Waste water treatment by flocculation is a chemical process and discharging the cleaned water to drain is controlled by strict governmental rules. In addition, chemical water treatment requires qualified personnel with an in-depth knowledge of the treatment process and the required adjustments.

How you can save money with process water recycling

Our company philosophy has always been guided by our desire for a sustainable protection of the environment: “Prevention of waste is always better than its disposal.” We feel that whenever technically possible the process water should be re-used in a recycling system. In other words: Waste water that is not generated, must not be cleaned!”

For this reason, as a first choice we recommend the use of recycling centrifuges. Based on our experience with hundreds of systems operating in the field we have found that process water recycling with centrifuges is by far the best alternative for 80 – 90% of all mass finishing applications. It is a purely mechanical process that protects not only the environment but also helps reduce capital expenditures as well as the costs of operation and waste disposal.

basket centrifuge

Dr. Andreas Funk adjusting a ZM 03 basket centrifuge.

Centrifuges are separating the solid contaminants from the liquid phase with a centrifugal force corresponding to about 2000 g. While the solids are deposited on the wall of the rotating drum in the form of sludge, the liquid – a mixture of water and compound – remains on the inside. From there the now clean process water is returned to the mass finishing process.

Centrifugal filtering proves convincingly that environmental protection can actually save money. If a user changes from using fresh water in flow-through/loss mode to process water recycling, he will save up to 80% in compound and 98% in water usage.

The capital expenditures for a centrifuge are significantly lower than those for a water treatment plant. And the users have lower waste disposal costs, because compared to the sludge quantity generated by flocculation systems, the amount of sludge is cut in half. Moreover, no discharge approval from the water authority is needed. This eliminates a lot of time-consuming bureaucracy.

Minimal expenses for waste disposal

With process water recycling the expenses for waste disposal are surprisingly low. The cleaned water is re-used in the finishing process, and no liquids are discharged to drain. Of course, some of the process water evaporates or is carried out of the system with the work pieces. These losses, usually just a few liters per week, must be replenished.

The utilized compound does not evaporate and remains in the process water. A small portion is lost with the water carried out of the finishing machine by the work pieces. From time to time the minor compound losses, like with the water, must be replaced. But as I said, these losses are minimal.

All that must be disposed of, is the sludge. It consists mainly of media fines. In addition, it can contain metal ions, colloids, some fines from the work pieces and, possibly, debris from burs, gates and risers, etc. Sometimes it also contains oil that was carried into the process by the work pieces such as stampings.

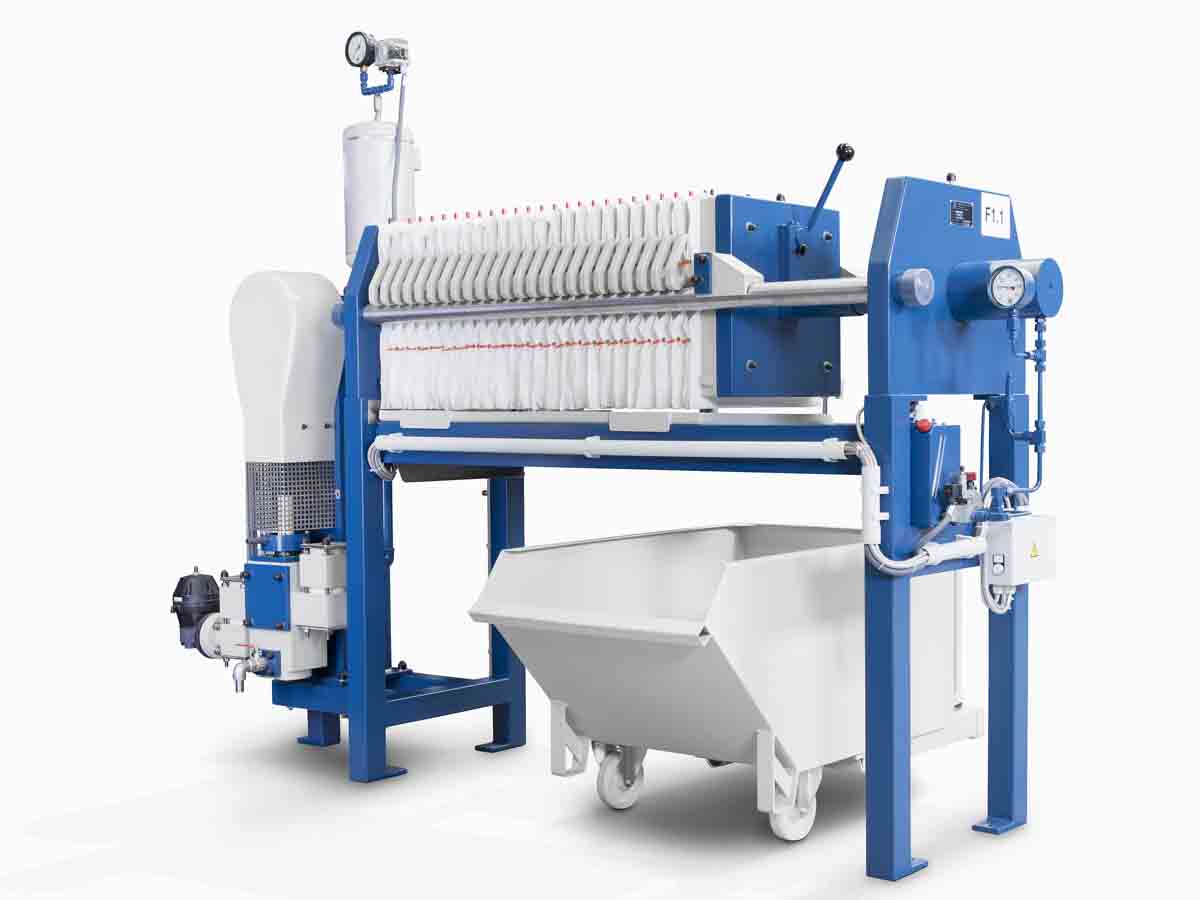

The sludge dried in a chamber filter press can be disposed of as solid waste per the disposal rules for abrasives used in honing and grinding operations. The respective sludge quantities are determined by the amount of generated media fines. The following rough rule of thumb provides a good estimate of the sludge quantity: A consumption of 70 kg of finishing media per cubic meter of water generates about 100 kg of sludge. Therefore about one tenth of the weight that would be generated, if the entire process water was disposed of. Since the disposal companies usually base their fees on the weight of the waste material, this is an important cost factor.

No special knowledge required

Centrifugal filtering is a simple mechanical technology that requires no special chemical knowledge. The centrifuge is simply turned on and off. That’s all. As a matter of fact, once they are set, the operational parameters do not have to be changed. This means that the recycling process is very safe and totally stable.

Whenever the process parameters are changing – for example, a different compound or media is used, or the metal alloy of the work pieces has changed – the user simply contacts the specialists at Walther Trowal to recalibrate the process. In addition, with the annual preventive maintenance work per accident prevention regulations we offer a regular technical service that is in full compliance with the legal requirements.

Sludge removal – manual or automatically?

For removing the sludge from the centrifuge we offer two possibilities. The choice depends on the amount of solids in the process water.

In so-called basket centrifuges the solids are collected in a sludge basket inserted into the rotating drum. Once the basket is full, it is removed from the drum and emptied. Provided the basket must be emptied only about one time per shift, this is very economical. Such relatively small sludge quantities can be easily handled with one IBC container per month.

When larger sludge quantities are generated, so-called peeling centrifuges represent the better alternative. In these centrifugal systems the sludge is automatically peeled from the rotating drum in pre-set time intervals and dumped into a sludge container. Since the container has a large holding capacity, it does not have to be emptied very often.

The right specification is crucial

The centrifuge size (capacity) depends less on the amount of recycling water but more on the amount of generated sludge. For example, a user must make sure that the sludge basket is big enough to safely remove all solid particles accumulating in the recycling system. In this respect we can help our customers with a wealth of empirical data.

Let me illustrate this with a practical example: Let’s assume that a customer utilizes a medium size centrifugal disk finishing system, for example, a Walther Trowal machine, model TT 90, with small, relatively fast cutting ceramic grinding media. Per hour about 80 to 100 liters of water are passing through the finishing machine. If you only take the water flow into consideration such a water volume can normally easily be handled by a basket centrifuge. However, the media consumption amounts to around 7 kg/hour. When adding 3 kg/hour residual water content in the sludge, the total hourly sludge quantity increases to 10 kg. This would require emptying the sludge basket every 2 hours. In this case an automatic peeling centrifuge is therefore much more economical and relieves the operator from strenuous manual work.

The limits of centrifugal filtering

Of course, centrifugal filtering cannot be used for every mass finishing process. With some applications the process water cannot be re-cycled. For example, when acidic compounds are used for pickling operations, it is difficult to consistently maintain the right pH value, because the process water always contains acids, additives and residual surfactants. This makes the targeted water/compound replenishment very difficult so that it is safer to use fresh water in flow-through/loss mode.

Also, in multi-stage processes where multiple compounds are used at the same time, the process water must be cleaned in a flocculation system and subsequently be disposed of.

Flocculation: A wastewater cleaning system for special applications

If the work piece surface requires particularly high finishing qualities, for example, a high degree of cleanliness, flow-through processing mode with fresh water is recommended. Flocculation performed after the mass finishing process removes the solids as well as oil and grease from the process water

Flocculation systems are reliably removing solids as well as oil and grease from the contaminated process water. Therefore, the cleaned water can be discharged to drain in full compliance with the legal requirements. This usually works very well. But in most cases process water recycling with centrifuges is more eco-friendly and more economical.

And who helps me, when I have to deal with difficult mass finishing processes?

You can always turn to our experts for advice. In most cases they are able to develop solutions that allow running finishing processes with process water recycling. In our test lab in Haan they will analyze process water samples to determine how finishing processes can be run in recycling mode and what equipment modifications will be necessary.