The new multivibrator MV 50 system reduces the finishing time for large work pieces from literally days to a few hours. With an internal diameter of 1,650 mm the multivibrator MV 50 is the largest of this machine type we have ever built. It fully automatically finishes the surface of components with a diameter of up to 1,300 mm in one single operation.

Rotors and turbine disks for jet engines have one thing in common: The quality of their surface finish and the contours of their edges determine to a large extent the efficiency of the air flow and, therefore, the overall efficiency, fuel consumption and noise emission. Likewise, the forging tools must have a perfect surface finish to make sure that the finished forgings meet the strict quality specifications.

A smooth surface and precisely radiused edges

A manufacturer of jet engines has been using mass finishing equipment for many years. For the treatment of blisks (“blade integrated disks”) with diameters of up to 1,300 mm he wanted to further streamline the manufacturing operation. This included a faster, more gentle and more precise finishing of the surface and the edges. In addition, the customer insisted on a finishing process that consistently produces high quality results and, to a large extent, runs fully automatically.

Fast and gentle

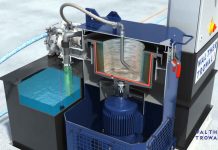

To fulfill these customer requirements we decided to develop the M 50. With an internal diameter of 1,600 mm it is by far the largest multivibrator and a valuable addition to our equipment range. In contrast to tub vibrators the work pieces are individually mounted to the bottom of the processing bowl. With this work piece arrangement the media exerts a much higher pressure on the work piece surface. Therefore, with the MV 50 equipment design the processing times for a typical work piece are reduced from several hours to 90 minutes.

The work piece is attached to the bottom of the processing bowl (center). The media is automatically transferred from the lower intermediate storage hopper to the upper loading hopper.

The processing bowl has an internal diameter of 1,600 mm.

Automatic operation guarantees absolutely consistent finishing results

The new machine was designed for fully automatic operation: After a work piece has been mounted to the bottom of the processing bowl, no additional manual operations are necessary. This ensures high process stability and absolutely consistent finishing results.

Especially for the production of components for jet engines manual operations should be prevented at all costs because they are frequently the reason for poor and inconsistent finishing results. Therefore, when developing the new vibratory finishing machine, we looked at the entire process – even at the automatic replenishment of the processing media into the work bowl and the cleaning of the process water. We made sure that with the new multivibrator all surface areas on the work pieces are evenly finished with excellent and consistent results.

Dipl.-Ing. Christoph Cruse, General Sales Manager at Walther Trowal

For the vibratory finishing of blisks Walther Trowal utilizes plastic processing media, type AF. On the typical materials used for making these geometrically complex work pieces they produce extremely smooth and homogeneous surface finishes with very low surface roughness readings.

Intensive contact between media and the work pieces

One work piece at a time is externally mounted to a specially designed fixture. An integrated loading crane places the fixture with mounted work piece into the processing bowl where it is magnetically fastened to the bottom. In the next step the bowl is automatically filled with media and vibration is induced into the machine by two vibratory motors mounted to the outer wall of the processing bowl. Since the work piece is firmly attached to the processing bowl, the motion of the media against the work piece is very intensive. But at the same time the overall process is rather gentle. This applies equally to external as well as internal surface areas and thus produces a highly homogeneous finish of the entire work piece surface. After completion of the process the surface roughness readings amount to about 0.2 to 0.4 µm. Since the vibratory amplitude in the multivibrator systems is rather low, very little material is removed at the functional edges of the work pieces.

Continous recycling

Upon completion of the finishing process the pneumatically activated unload plug in the processing bowl is opened. This causes the media to be discharged from the processing bowl into a storage hopper. From there the media is passing over a bar screen to remove undersized media and is then transported to the conveyor belt.

Any residual media sticking to the finished work pieces is automatically rinsed off with a pneumatic rinse nozzle that moves – guided by laser sensors – across the entire work piece surface. A camera system allows the operator to check if all residual media has been removed from the work pieces. The process water is cleaned in a centrifuge and returned to the finishing machine in a closed loop system.

Always the optimal media level

As soon as the fixture holding the next work piece has been attached to the bottom of the processing bowl, the media from the storage hopper is automatically returned into the processing bowl. Since components for the aerospace industry must have absolutely stable, consistent surface finishes, the media batch in the storage hopper is automatically weighed, and if needed, additional media is automatically added. This is very important, because during the finishing process the media wears and becomes smaller. Over time this would result in a lower media level in the processing bowl causing the finishing qualities to deteriorate. The automatic media replenishment ensures that the process remains stable and consistent. Manual process adjustments are, therefore, reduced to a minimum.