Whenever a large airplane arrives at its final destination after a long trip, for example, the airbus A380, many hours since the first meal onboard may have passed. This means that leftover food and gravy are usually baked onto the cutlery pieces. Within an extremely short time span the airline caterers must clean thousands of cutlery pieces and return them clean, dry and free of germs for the next trip. The solution for resolving this dilemma is the BRA cutlery cleaning system from Walther Trowal.

To date, the cleaning of soiled cutlery, especially in case of dried-on food leftovers, was rather difficult and costly. It required a lot of time and personnel for pre-sorting, pre-rinsing or time-consuming soaking, polishing and drying. Moreover, since all cutlery pieces were seldom completely clean, dry and spot-free, expensive controls and rework were necessary. On average, up to 15 % of the cutlery pieces had to be cleaned for a second or, even, a third time. In addition, the energy requirements for heating and drying with hot air were substantial.

The alternative: BRA

With its BRA cutlery cleaning systems we took a completely different, more cost-efficient approach: They clean thousands of cutlery pieces per hour fully automatically. The cutlery discharged from a Trowal cleaning system is absolutely clean, completely dry, without any water spots and free of germs. The Trowal equipment saves not only personnel and operating costs, but it also contributes to a significant reduction of cabin reports due to soiled cutlery. For quite some time the Trowal BRA cutlery cleaning systems have proven their effectiveness and cost-efficiency at numerous airline catering companies.

In one single automatic operation the cutlery is cleaned, rinsed and dried without any leftover water spots. The costly manual pre-cleaning or soaking, required with conventional cutlery cleaning systems, has been completely eliminated. Expensive post-polishing by hand is also no longer necessary.

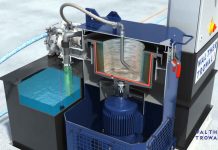

A Trowal cutlery cleaning system consists of two parts: A cleaning/rinse machine and a drier. The soiled pieces are randomly placed into the vibrating processing bowl of the cleaning machine. The bowl itself is filled with porcelain polishing media that was specifically developed for cutlery cleaning and a special detergent. The porcelain media pieces are a bit smaller than rice grains. This allows them to reach every corner and crevice. At the same time, they do not get stuck between the tines of the forks.

Gentle and sustainable

The food residues carried into the machine with the cutlery pieces are pulverized by the porcelain media and, together, with the detergent and water, completely discharged from the cleaning machine. The cleaned cutlery is then automatically transferred into the subsequent drier, also vibrating. The special, germ-free drying media, heated to a temperature of over 65 °C, completely dries the cutlery in an exceptionally gentle manner. The drying media consists of Maizorb – shredded corn cobs – and consists to 100 % of renewable material. The now clean and dry cutlery pieces are discharged from the drier with a chute and are collected in special baskets or transferred to a conveyor belt for sorting. The overall result is spot-free, shiny cutlery free of germs, ready for the next trip.

Fast return on investment

Numerous BRA installations have proven to quickly pay for themselves: On average the cutlery cleaning costs decreased by about 30 %, and the amortization period amounts to just a few months.

For example, at the airport in Zurich Gate Gourmet company was able to reduce the costs for cutlery cleaning with a BRA system by two thirds. On average this system cleans 40,000 cutlery pieces per day, during peak times up to 70,000. In the past about 50 to 100 kg of cutlery had to be cleaned a second time every day. With the Trowal system this number was reduced to less than 0.5 kg. Within the first 6 months after the commissioning of the BRA equipment only two cabin reports, due to soiled cutlery, were received. The consumption of cleaning detergent was reduced to 150 grams per operating hour, and the hourly freshwater usage declined to 300 liters. Similar results were achieved with a Trowal cutlery cleaning system at the airport in Toronto.

At a renowned airline caterer 99.8 % of the cutlery left the Trowal system perfectly clean one week after commissioning: While with the previous cleaning method 15 % of the cleaned cutlery had to be reworked, with the BRA the rework rate was reduced to 0.2 %. Another customer reported that the personnel costs for cutlery cleaning could be lowered by 20 %. Furthermore, the time for rework could be cut to practically zero. The same impressive results were reported by EverGreen Skycatering at Taipei airport with substantially lower operating costs and a near-zero reject rate.

With the three-stage hydro-mechanical „HDS technology“ Walther Trowal was able to decrease the expensive cost factors chemistry, temperature, energy and personnel for cutlery cleaning operations. They were replaced by the mechanical, but gentle, interaction between the cutlery pieces and special cleaning media made from porcelain. With the HDS method the heating costs could also be reduced: The system works effectively already at temperatures of 20 °C. This results in a reduced consumption of electric power, water and detergent by up to 70 %.

In addition, the gentle cleaning process significantly extends the usable life of the cutlery. Therefore, fewer cutlery pieces must be replaced due to wear. This means that the cutlery can be re-used for a long time – an excellent example for sustainability!