Is the subject “mass finishing” new for you? Do you want to gain a quick overview over the possibilities and the latest technologies? Then you must read our new white paper!

Who, if not the inventor of the mass finishing technology, is in a better position to describe the technology and its applications?

Our experts explain in a few words, how the right combination of machine, grinding or polishing media and compounds will help you achieve technically and economically optimal finishing results that are precisely adapted to your specific requirements.

Find out…

- …how your work pieces can receive a high value surface finish,

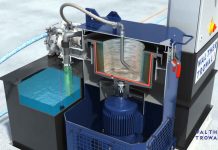

- …how mass finishing works,

- …which is the best machine for treating your work pieces,

- …how you can seamlessly integrate the “trowalizing” process into your

manufacturing operation.

These are the subjects:

- Deburring and edge radiusing

- Surface smoothing and polishing

- Cleaning and degreasing/de-oiling

- Descaling and derusting

Here you navigate to the free-of-charge download: White paper Mass finishing