APO: Absolutely perfect surface finishes

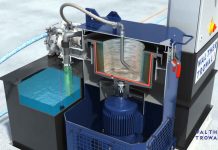

APO – Pursuing Absolutely Perfect finishing Objectives: While this word play is a good description of the company’s philosophy, its name actually originated from the initials of the founder, namely Antonio Pozo. The coating job shop, located in the former coal region around the city of Aachen in Germany operates ten Rotamat coaters from Walther Trowal round the clock in three shifts. Every year around one billion parts are being coated.

APO purchased its first Rotamat, model R 90, in 2002, the year the company was founded. Since that time a close partnership has developed with Walther Trowal. This cooperation has no doubt contributed towards the fact that today the drum coating of plastic components is the generally recognized standard.

In our application report you will learn,

- Why APO, after having purchased the first Rotamat coater, acquired nine more machines,

- How the Rotamat coaters are integrated into the production control system of the company,

- How APO achieves homogeneous surface qualities with an even coating thickness and with absolutely consistent results,

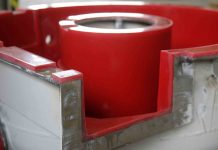

- How the system of easily exchangeable rotary drums ensures a high degree of manufacturing flexibility.

Read here what the ipcm magazine writes:

Link to downloading the pdf file: Application Report