BUVO castings is transforming the surface finishing of aluminum die-castings from batch processing to a continuous feed operation with rotary vibrators from Walther Trowal.The finishing equipment is completely integrated into the production flow. This allows the company to significantly reduce its capital expenditures and operating costs. At the same time it frees up a lot of space in the die-casting facility.

BUVO, an aluminum die-casting company in the Netherlands, specializes in producing and machining complex die-castings. With 17 die-casting cells and 85 machining centers 250 employees produce die-cast products with weights from 0.5 to 15 kg. The product range includes chassis and powertrain components for automobiles and motor bikes as well as housings for machinery, tele-communication and medical engineering. The volume of components for electric vehicles is growing rapidly.

At the moment BUVO is utilizing a dozen Walther Trowal mass finishing machines for deburring and cleaning its die-castings after the casting process. BUVO had already purchased its first machine in 1999. At that time the company chose the Trowal equipment for technical reasons but also, because of the excellent communication with the experts in Haan, who are always available on short notice.

Shorter processing time

During the past years a strong, cooperative business relationship has developed between BUVO and Walther Trowal. Within the framework of common projects BUVO has discussed its everyday production requirements with the engineers at Walther Trowal. On these occasions different viewpoints were openly discussed and the jointly developed solutions quickly implemented.

Over time the requirements of BUVO and its customers have become more stringent. To keep pace with this development the company continuously refined its production methods. For example, due to improved casting technologies the die-castings nowadays have less pronounced burs compared to a few years ago. This resulted in significantly lower cycle times for the deburring equipment. In this respect the in-house tool shop and the close communication between the design engineers and the shop floor personnel had a tremendous positive impact.

From linear finishing equipment to rotary vibrators

In the beginning BUVO used Trowal linear continuous flow vibrators, model range AV, with a length of up to 7 meters. The work pieces are fed into the machine at the inlet zone, are passing through the tub and are discharged through the separation station, where the finished work pieces are separated from the processing media. After BUVO was able to reduce the finishing times to only 5 to 6 minutes, the large continuous flow machines turned out to be somewhat oversized.

Through discussions with Trowal the company learnt that rotary vibrators can be operated with similar cycle times. Compared to the linear continuous flow vibrators the processing media does not have to be returned back into the inlet zone of the machine. However, a disadvantage was that the work pieces had to be loaded into the rotary machines in complete batches.

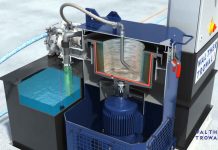

To eliminate the batch processing mode, BUVO had the idea to equip a Trowal rotary vibrator of the model range CB with an infeed chute in the outer wall to continuously feed the raw castings into the machine with a conveyor belt. The Walther Trowal engineers picked up this idea and modified one machine, which was commissioned at BUVO in 2018.

A major feature of the CB rotary vibrators is that their processing channel has a spiral shape providing a similar overall channel length as the linear continuous flow machines on a much smaller space: Even a very large rotary vibrator requires less space than an AV machine. This is a major benefit for many foundries.

The work bowl has a spirally shaped processing channel with a continuous incline. The RPM of the vibratory motor induces a spiral forward movement of the mix of media and work pieces towards the machine exit. A welcome side effect of this unique vibratory equipment design is that the media exerts additional pressure on the castings resulting in faster processing times.

Integration into the critical path

Over the course of the past years BUVO has continuously improved its manufacturing processes. When the company was founded, manual deburring and polishing were common, while today all processes are interlinked with each other. The high degree of automation of the entire production is a major reason for the high productivity and the proven quality of the castings.

But this could only be achieved by integrating the surface finishing operation into the production process by placing the finishing equipment directly behind the die-casting cells. For the mass finishing machines this means that they are part of the critical path. If, for whatever reason, they were not operational, after a short while the die-casting operation would come to a stand-still, because the raw castings cannot be diverted to other finishing machines.

It became quickly obvious that the uptime of the mass finishing machines played a critical role in this integrated manufacturing concept. Since the Trowal machines had shown to be extremely reliable over a long period of time, the decision to integrate them into the manufacturing process was easy: During the past 10 years BUVO had to ask Walther Trowal only two times for onsite technical support.

The experience to date: Only positive

With the first modified machine BUVO had assumed a true pioneering role in the die-casting industry. Today the company is successfully operating five of these finishing machines. The experience from several years of operation confirmed that a cycle time of five to six minutes is sufficient, and that the decision to use CB rotary vibrators was the right one.

The switch from linear machines to rotary vibrators has significantly improved the overall production flow. Now the shop floor personnel can focus on the casting process, because the surface finishing operation is running by itself and requires very little attention.

The operation itself has been immensely simplified: All that needs to be done at the beginning of a shift is turn on the machines. The rest takes place fully automatically: The work pieces arrive in single piece flow at the in-feed chute at time intervals, which ensure that they do not touch each other when travelling through the rotary finishing machine.

Since the CB rotary vibrators are equipped with a media undersize screen at the machine exit, the media operating mix is always optimal. As soon as individual media pieces wear below a defined size, the undersize screen automatically discharges them from the machine. This makes certain that the media mix in the processing bowl remains with a specified size range. Loose burs and dirt particles also fall through the undersize screen so that the media always stays clean.

The processing bowl exchange program from Walther Trowal has also been a great advantage: Whenever the wear lining of a processing bowl is reaching the end of its usable life, Walther Trowal immediately supplies an overhauled unit. This prevents not only any production downtimes but is also a contribution towards sustainability and protection of resources by both companies.

The rotary vibrators offer the same productivity as the linear AV machines but at significantly reduced costs. Since auxiliary equipment like media return conveyors, stand-alone driers and noise protection cabins are no longer necessary, the purchase price for rotary vibrators is significantly lower. The rotary vibrators run fully automatic and require no longer any adjustment of the machine settings. This also helped to reduce the labor costs.

A glimpse into the future

The surface finishing requirements will no doubt become more strict. For this reason the equipment must be adaptable for the challenges of the future. Whenever the team at BUVO is faced with challenges that cannot be met with the existing configuration of equipment, media or compound, they contact the experts at Walther Trowal. Jointly conducted processing trials in the test lab in Haan so far have always produced practical and economic solutions to these challenges.

Within the near future, whenever the lining of a linear finishing machine is worn and should be renewed — BUVO will replace this machine with a rotary vibrator. For sure today BUVO would take a different approach than in the past: For a new project completely from scratch the company would only purchase rotary vibrators with work piece infeed chute.