Whenever we talk with our customers, we come to the same conclusion: Additive manufacturing has evolved from a prototyping method to a technology for volume production. But for many 3D printed components the manufacturing process must be further improved.

For this reason, our trading partners are relieved to learn that they do not have to invest additional development work in surface finishing: The “trowalizing” process allows them to achieve perfect surface finishes.

A proven finishing method for an innovative manufacturing technology

Additive manufacturing offers the engineers a degree of design freedom that to date was impossible. Most 3D printed components are produced by placing material layers on top of each other, creating a “staircasing” effect on their surface with a, generally, very high initial surface roughness. Also, before the components can be further processed or utilized, most of the time the markings of removed support structures and sintered-on powder residue must be removed. Therefore, most 3D printed components must undergo an intensive surface smoothing or polishing operation.

Topologically optimized work pieces with complex – frequently bionic – shapes often have difficult-to-reach internal passages. Manual finishing of these surface areas is not permissible, especially when the work pieces are subject to strict safety and manufacturing standards, which is the case, for example, in the aerospace industry. Recently, mechanical finishing has become even more important, because 3D printing is increasingly used for serial manufacturing with continuously growing production volumes.

Mass finishing has proven to be the ideal surface refinement method for components made by additive manufacturing. Both technologies represent an ideal combination: The grinding or polishing media, flowing around the work pieces, refines the surface gently, evenly and produces absolutely repeatable results. In addition, the media also reaches internal passages and undercuts in the components to be finished.

Compared to other methods the single stage mass finishing process significantly shortens processing times. The process can be further optimized, if surface finishing aspects are already taken into account during the design phase for a 3D printed product and during the printer parametrization. For example, the latter applies to setting the thickness of the material layers, the material feed rate and and the travel speed of the laser beam. We are gladly lending our support to our customers for resolving these issues.

An ideal match for additive manufacturing

“Trowalizing” reduces the initial surface roughness of 3D printed components from Ra = 2 – 80 µm to a value of around 0.025 µm. For example, this is an ideal surface finish for turbine blades requiring a minimum of friction for the airflow. Also, mass finishing generates a homogeneous peening effect on the surface of components requiring a high degree of hardness and stability. Mass finishing is especially effective in case of bionic shapes, which are typical for 3D printed components.

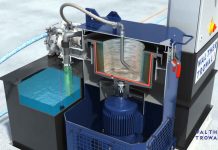

On the basis of our proven multivib vibratory technology we have developed “AM post process machines” that are tailormade for additive manufacturing. They are equipped with three vibratory motors inducing overlapping vibratory movements. These generate a highly homogeneous, smooth surface but leave the edges intact. The work pieces are mounted on a carrier plate in the bottom of the processing bowl. Once they are in place, the media is loaded, and the vibratory motors induce a vibratory motion. This causes the media to flow around the work pieces generating a smoothing effect on their surface. After a pre-determined cycle time the process is completed, and the finished work pieces can be removed.

A perfect surface finish in surprisingly short cycle times

Contrary to electro-chemical finishing methods we achieve smoothness and luster in one single process stage. Another benefit is that mass finishing machinery is generally very compact requiring relatively little floor space. The result: Mass finishing produces optimal finishing qualities in short processing times and is, therefore, highly cost-efficient. This applies to the initial capital expenditure but also to the operating costs.

The optimum finishing parameters for each individual work piece are, jointly with the customers, determined through processing trials conducted by the process engineers at the Walther Trowal test center. This also includes the selection of the most suitable grinding or polishing media and compound.

The “trowalizing” process can be used for any 3D printed components, irrespective of the material they are made of, whether this is a high-strength, difficult to machine metal like titanium or a nickel based or cobalt chrome alloy. It can also be used for non-ferrous metals and plastic, actually for any material Walther Trowal has dealt with during the last decades.

It is worth mentioning that our grinding and polishing media are already approved for many materials, safety components and processes.